Product Consultation

Your email address will not be published. Required fields are marked *

In the textile world, nylon elastic yarn used to be a “quiet” material. It wasn’t the star of the show, and it didn’t grab headlines.

But lately, manufacturers are hearing the same question over and over again:

“Can this yarn give the stretch we need without breaking or losing shape?”

That question is pushing nylon elastic yarn into the spotlight, because more products now demand comfort, durability, and high elasticity—especially in sportswear, underwear, and functional textiles.

Nylon elastic yarn is a type of stretch yarn made from nylon (polyamide) and often combined with elastic cores or special processing to provide high elasticity and recovery.

Unlike regular nylon yarn, which is strong but not very stretchy, nylon elastic yarn can stretch and then return to its original shape.

That’s why it’s used in products where fit and comfort matter, and where the fabric needs to “move with you” rather than stay rigid.

Because the market has shifted. Consumers aren’t just buying clothes anymore—they’re buying comfort, performance, and long-term value.

When a garment stretches out and never comes back, customers don’t just complain—they stop buying that brand.

Nylon elastic yarn matters because it directly affects:

- Fit and comfort

- Shape retention

- Durability

- Product quality perception

In many ways, it’s the difference between a garment that feels “cheap” and one that feels “well-made.”

It’s used in a lot of applications, especially where stretch is required without sacrificing strength.

Common uses include:

But it’s also used in industrial textiles where flexibility and resilience matter, such as certain safety fabrics or protective gear.

The magic is in the combination of materials and the manufacturing process.

Many nylon elastic yarns are made with a stretchy core (like spandex) wrapped in nylon fibers.

This gives the yarn strength and abrasion resistance while keeping stretch performance high.

Manufacturing processes like heat setting are used to stabilize the yarn so it doesn’t lose shape after stretching.

Without proper processing, the yarn can “creep” or permanently deform.

Stretch is how far the yarn can extend. Recovery is how well it returns to its original length.

Good nylon elastic yarn needs both. If it stretches well but doesn’t recover, the garment becomes loose over time.

Nylon elastic yarn offers big benefits, but it’s not perfect for every application.

So manufacturers need to choose carefully based on end-use and customer expectations.

In real production, the most common issues come from mismatch between yarn performance and product expectations.

Different products need different stretch levels. Underwear needs a different stretch profile than sportswear or socks.

Many products fail not because of initial stretch, but because of repeated washing and wear.

Manufacturers should test yarn performance after multiple wash cycles.

Elastic yarns can sometimes feel tight or less breathable if the fabric construction isn’t right.

Balancing stretch with comfort is key.

Yarn elasticity can vary between production batches. That affects fabric tension and garment fit.

Manufacturers should have strict quality control and supplier communication.

The demand for nylon elastic yarn is growing because end-users are demanding more comfort and better fit in everyday clothing.

At the same time, the market is also becoming more competitive. Customers are expecting higher performance at lower costs.

That means manufacturers who can offer stable quality, reliable supply, and clear technical support will win more business.

Nylon elastic yarn may not be a glamorous material, but it’s one of the most important components in modern textiles.

It’s the difference between clothing that fits well for a month and clothing that still feels good after a year.

For manufacturers, the key is not just producing elastic yarn, but producing it consistently and matching the right yarn to the right application.

When that happens, customers feel it every time they wear the garment.

Are the diameter and surface quality of the nylon monofilament yarn uniform and consistent?

2026-01-08

How are the heat resistance and UV resistance of nylon mother yarn?

2026-01-22Your email address will not be published. Required fields are marked *

Antiviral nylon Monofilament Yarn can inhibit the survival of viruses on the surface of the yarn, which can effectively reduce the risk of virus transmission and improve user safety. The yarn has a mo...

See Details

Colored Nylon Mother Yarn can be processed through spinning, drawing, dyeing and other processes to meet the needs of different textiles. It has good processing adaptability and can be made into vario...

See Details

The diameter of Durable woven nylon mother yarn is 240D, the fiber thickness is medium, and it is suitable for the manufacture of a variety of textiles. This product has good tensile strength and will...

See Details

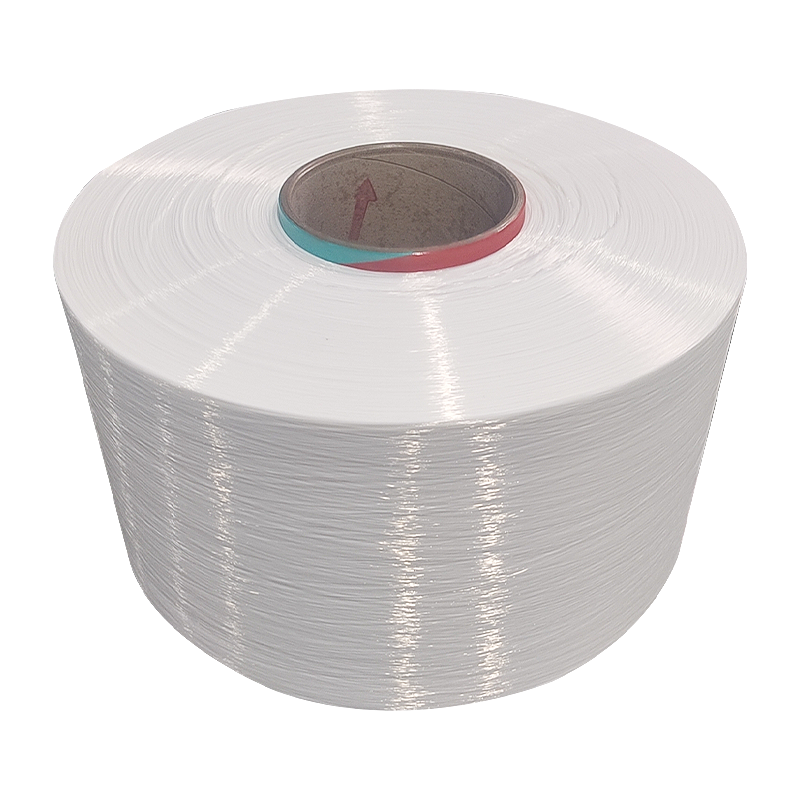

Nylon Elastic Yarn has elasticity and can quickly return to its original shape after stretching. This high elasticity makes the fabrics stretchable and comfortable. Nylon material has good wear resist...

See Details

Nylon stretch sportswear yarn is a yarn used to make sportswear and other clothing that require high breathability. Nylon fiber has good breathability, which helps to wick away perspiration and keep t...

See Details

Nylon elastic yarn for textile use has a wide range of applications. Nylon elastic yarn is suitable for the manufacture of various textiles, such as underwear, socks, sportswear, swimwear, elastic fab...

See Details

100D Nylon Elastic Yarn has a moderate thickness and good dyeing properties, which can achieve uniform and durable dyeing effects, making textiles bright and long-lasting in color. A yarn frequently u...

See Details

Durable composite nylon yarn has stretch and recovery properties, providing the necessary comfort, fit, and flexibility for clothing and textiles. Made of a blend of nylon fiber and polyester fiber, i...

See Details

210D Polyester Nylon Composite FDY yarn is a composite fiber yarn. FDY is a mixture of polyester and nylon fibers. It combines the advantages of the two fibers, the abrasion resistance of polyester an...

See Details

High shrinkage blended polyester yarn has a high shrinkage rate and is suitable for textile manufacturing that requires shrinkage treatment, such as making pleated fabrics or textile shaping. Because ...

See Details

Stretch durable FDY yarn has good elasticity and can return to its original shape after being stressed, giving the textile a comfortable wearing feel and good ductility. It can fit the contours of the...

See Details

The fibers of 210D water-repellent yarn are relatively thick, making the yarn highly wear-resistant and durable, making it suitable for long-term use. Composite fiber enables yarn to have the advantag...

See DetailsAddress: Duntou industrial park, haian county, nantong city,jiangsu province ,China.

TEL: +86 15850491859

E-mail: sales-betty@hsnylon.com

If You Are Interested In Our Products, Please Consult Us