Advantages of Nylon Multifilament Yarns

The primary advantage of Nylon Multifilament Yarns is their excellent physical properties. The multifilament yarn structure gives Nylon yarn high strength and toughness, and can withstand large tensile and bending forces. This property gives Nylon Multifilament Yarns a significant advantage when manufacturing products that require high durability and strength, such as outdoor gear, sportswear, and automotive interiors. Additionally, Nylon Multifilament Yarns offer excellent wear and scratch resistance, maintaining their appearance and performance over extended periods of use.

In addition to excellent physical properties, Nylon Multifilament Yarns also have good elasticity and resilience. This characteristic allows Nylon yarn to quickly return to its original shape after being subjected to external forces, maintaining the flatness and comfort of the fabric. In the field of clothing, this kind of elasticity and resilience can ensure that clothing stays close to the body during wearing, while providing a comfortable wearing experience.

Nylon Multifilament Yarns also offer excellent chemical resistance. It is resistant to a wide range of chemicals, including acids, alkalis, greases and solvents. This property gives Nylon yarn a distinct advantage when manufacturing products that require contact with chemicals, such as industrial textiles, protective clothing and medical supplies. In addition, chemical resistance also ensures that Nylon yarn is not easily damaged during washing and maintenance, extending the service life of the product.

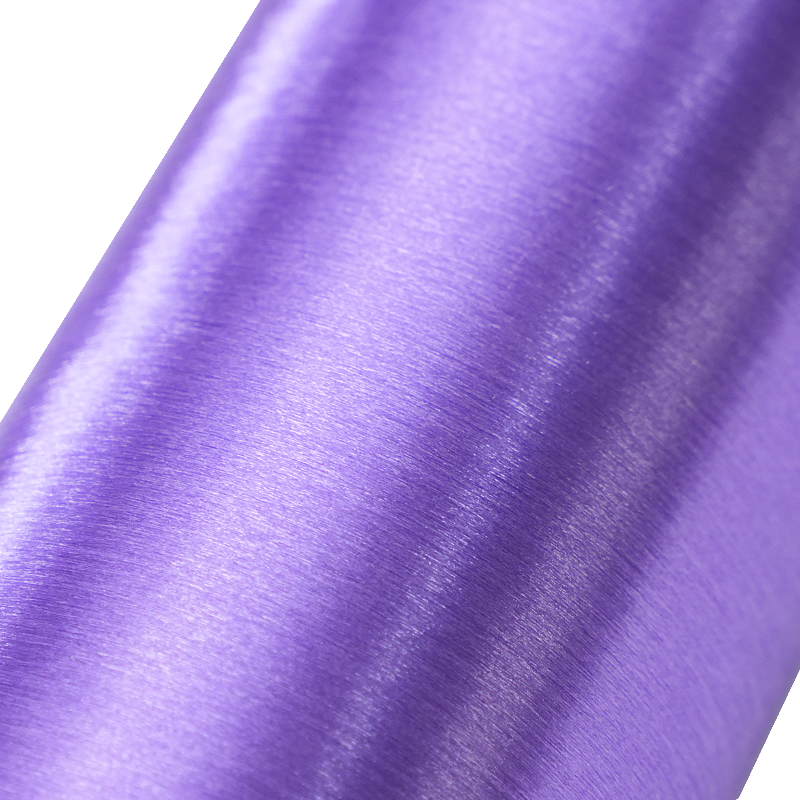

Another advantage of Nylon Multifilament Yarns is their good dyeability and processability. The yarn absorbs dye easily and produces vibrant, long-lasting color. At the same time, Nylon yarn also has good processability and can be processed and formed through various textile processes, such as knitting, weaving and sewing. This gives Nylon Multifilament Yarns great flexibility in manufacturing textiles with a variety of complex structures and patterns.

Nylon Multifilament Yarns plays an important role in the textile industry due to its excellent physical properties, good elasticity and resilience, excellent chemical resistance, good dyeability and processability, and wide range of applications. With the continuous advancement of technology and the growing demand of consumers, Nylon Multifilament Yarns will continue to leverage its advantages in the textile industry to bring people more high-quality, comfortable and durable textiles.

Wide Application of Nylon Multifilament Yarns

In the clothing industry, Nylon Multifilament Yarns is favored for its high strength, wear resistance and scratch resistance. It is widely used in sportswear, outdoor equipment and casual wear. Sportswear needs to have good elasticity and breathability to ensure that athletes can stay comfortable and flexible during exercise. The excellent performance of Nylon Multifilament Yarns makes it an ideal material for making sportswear, providing athletes with an excellent wearing experience. In addition, outdoor equipment also needs to have wear resistance and scratch resistance to cope with various harsh environments. The excellent performance of Nylon Multifilament Yarns makes it an ideal choice for outdoor equipment, providing reliable protection for outdoor enthusiasts.

In the home field, Nylon Multifilament Yarns also shows a wide range of application prospects. It is used to make home textiles such as curtains, carpets, and bedding. Curtains need to have good light blocking and wear resistance to cope with long-term sunlight exposure and frequent use. The excellent performance of Nylon Multifilament Yarns makes it an ideal material for making curtains, providing a beautiful and practical choice for the home environment. Carpets need to be soft, comfortable and wear-resistant to meet people's daily use needs. The elasticity and resilience of Nylon Multifilament Yarns make carpets softer and more comfortable, while its wear resistance also ensures the durability of carpets. Bedding such as sheets and quilts also need to be soft, comfortable and easy to clean. The softness and chemical resistance of Nylon Multifilament Yarns make it a high-quality material for making bedding, providing people with a comfortable sleeping environment.

In the industrial field, Nylon Multifilament Yarns also plays an important role. It is used to make protective clothing, industrial fabrics, filter materials, etc. Protective clothing needs to have good protective performance and durability to cope with various harsh industrial environments. The chemical resistance and wear resistance of Nylon Multifilament Yarns make it an ideal material for making protective clothing, providing reliable protection for workers. Industrial fabrics such as conveyor belts and screens also need to have high strength and wear resistance. The high strength and wear resistance of Nylon Multifilament Yarns make it a high-quality material for making industrial fabrics, meeting the needs of industrial production. Filter materials need to have high filtration efficiency and wear resistance. The fine structure and wear resistance of Nylon Multifilament Yarns make it an ideal choice for manufacturing filter materials, providing strong support for environmental protection and industrial production.

In addition to the above fields, Nylon Multifilament Yarns has also shown a wide range of application potential in other fields. For example, in the medical field, it can be used to manufacture surgical sutures, medical bandages and other medical supplies; in the automotive field, it can be used to manufacture car seats, interior parts and other components; in the military field, it can be used to manufacture military tents, camouflage nets and other military equipment. The expansion of these application fields further proves the wide applicability and strong potential of Nylon Multifilament Yarns.