Product Consultation

Your email address will not be published. Required fields are marked *

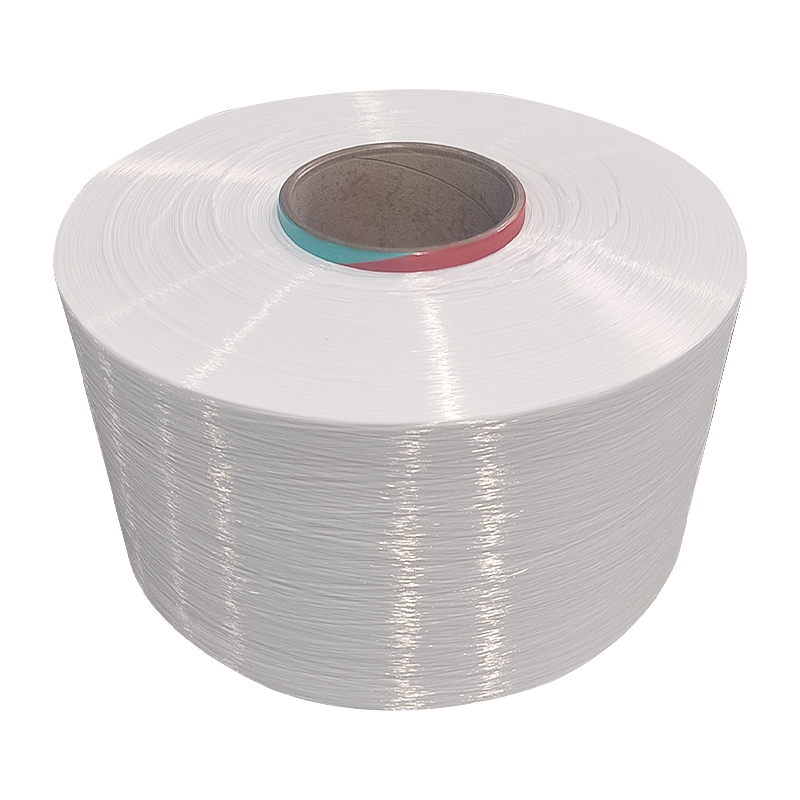

Introduction to Nylon Monofilament Yarn

Nylon monofilament yarn is a single-strand synthetic fiber widely used in industrial, commercial, and domestic applications. Its continuous structure provides specific mechanical properties such as tensile strength, flexibility, and durability, which are crucial for products like fishing nets, brushes, industrial filters, and textiles. Understanding the hygroscopicity and chemical stability of nylon monofilament yarn is essential for predicting its performance in various environments and selecting appropriate applications.

Understanding Hygroscopicity of Nylon Monofilament Yarn

Hygroscopicity refers to the ability of a material to absorb moisture from the surrounding environment. Nylon monofilament yarn, being a polyamide fiber, exhibits moderate hygroscopicity due to the presence of amide groups in its molecular structure. These polar groups form hydrogen bonds with water molecules, leading to water absorption. This moisture uptake can influence the yarn’s dimensional stability, mechanical properties, and performance under stress. For instance, the tensile strength of nylon monofilament yarn may slightly decrease under high humidity conditions, while elongation at break may increase due to the plasticizing effect of absorbed water.

The hygroscopicity of nylon monofilament yarn is affected by several factors, including ambient humidity, temperature, and the specific type of nylon used. Typically, nylon 6 and nylon 6,6 show different moisture absorption rates, which can impact their applications in environments with varying moisture levels. Designers and manufacturers need to consider this property when using nylon monofilament yarn in products exposed to water or high humidity.

| Nylon Type | Moisture Absorption (%) at 65% RH | Moisture Absorption (%) at 95% RH |

|---|---|---|

| Nylon 6 | 2.8 | 4.5 |

| Nylon 6,6 | 2.0 | 3.5 |

Factors Influencing Hygroscopic Behavior

Several environmental and material-related factors affect the hygroscopic behavior of nylon monofilament yarn. Temperature plays a significant role, as higher temperatures can increase the diffusion rate of water molecules into the fiber, leading to faster moisture uptake. Similarly, the duration of exposure to humid conditions can determine the equilibrium moisture content of the yarn. The filament diameter also contributes to hygroscopicity; finer filaments generally reach moisture equilibrium faster than thicker filaments due to their higher surface area-to-volume ratio.

The presence of additives or coatings on the nylon monofilament yarn can modify its hygroscopic behavior. For instance, hydrophobic coatings reduce water absorption, making the yarn suitable for outdoor or marine applications. Understanding these influencing factors helps in designing products that maintain performance under specific environmental conditions.

Chemical Stability of Nylon Monofilament Yarn

Chemical stability refers to the ability of a material to resist chemical degradation or reaction under various conditions. Nylon monofilament yarn demonstrates reasonable chemical stability against many organic solvents, oils, and mild acids. However, it is susceptible to degradation when exposed to strong acids, strong alkalis, or oxidizing agents. Prolonged contact with such chemicals can lead to hydrolysis of the polyamide chains, weakening the yarn and reducing its lifespan.

The chemical structure of nylon monofilament yarn, primarily composed of repeating amide linkages, is responsible for both its stability and vulnerability. While these amide groups confer good resistance to neutral chemicals, they are reactive toward hydrolytic agents. Understanding the chemical stability is critical for applications in chemical processing, industrial filtration, and environments where exposure to reactive substances is possible.

| Chemical Agent | Resistance Level | Notes |

|---|---|---|

| Water | High | Minimal effect under normal conditions |

| Mild acids | Moderate | Slight hydrolysis over prolonged exposure |

| Strong acids | Low | Significant hydrolysis and degradation |

| Alkalis | Moderate to Low | Can cause swelling and reduced tensile strength |

| Organic solvents | High | Generally stable, limited effect |

Relationship Between Hygroscopicity and Chemical Stability

The hygroscopic nature of nylon monofilament yarn can influence its chemical stability. Moisture absorbed by the yarn can accelerate hydrolysis in acidic or alkaline environments. High moisture content increases the mobility of reactive species within the fiber, facilitating chemical reactions that may not occur in dry conditions. Therefore, applications in humid or wet environments must consider both hygroscopicity and chemical stability to prevent premature degradation.

For industrial designers, this relationship is critical. For example, nylon monofilament yarn used in water filtration systems or marine nets needs to balance moisture absorption with resistance to chemical agents present in water. Proper selection of nylon type, filament diameter, and any protective coatings can help achieve the desired performance.

Applications Requiring Consideration of Hygroscopicity and Chemical Stability

Nylon monofilament yarn is widely used in industries that demand specific performance characteristics. In marine applications, high humidity and saltwater exposure necessitate yarns with low moisture sensitivity and good chemical resistance. In industrial filtration, resistance to oils, solvents, and cleaning agents is essential to maintain filtration efficiency over time. Textile applications, including threads for upholstery or sportswear, also require consideration of moisture absorption to avoid dimensional changes and maintain product quality.

| Application Area | Hygroscopic Requirement | Chemical Stability Requirement |

|---|---|---|

| Marine nets | Low to Moderate | High |

| Industrial filters | Moderate | High |

| Textile threads | Moderate | Moderate |

| Fishing lines | Low | Moderate |

Tips for Maintaining Performance

Proper handling and maintenance of nylon monofilament yarn can enhance its service life. Storing yarn in a controlled, low-humidity environment reduces unnecessary moisture absorption. Avoiding prolonged exposure to strong acids, alkalis, or oxidizing chemicals prevents chemical degradation. For outdoor or industrial applications, applying hydrophobic coatings or selecting specific nylon types with improved chemical resistance can improve durability. Routine inspection for signs of hydrolysis, swelling, or brittleness helps identify potential issues early, ensuring reliable performance.

Does bi-component FDY yarn have characteristics in terms of environmental protection and recyclability?

2025-08-11

How does nylon mother yarn affect yarn strength and elasticity during production?

2025-08-26Your email address will not be published. Required fields are marked *

Biodegradable nylon yarn biodegrades faster in the environment than traditional synthetic fibers, helping to reduce negative environmental impacts. It also has the properties of nylon fiber, such as h...

See Details

60D woven Antiviral Yarn is thin overall and suitable for making light and soft textiles. Nylon fiber has a soft feel and good breathability. This yarn is usually used to weave fabrics and can be made...

See Details

Nylon Elastic Yarn has elasticity and can quickly return to its original shape after stretching. This high elasticity makes the fabrics stretchable and comfortable. Nylon material has good wear resist...

See Details

Nylon stretch sportswear yarn is a yarn used to make sportswear and other clothing that require high breathability. Nylon fiber has good breathability, which helps to wick away perspiration and keep t...

See Details

100D Nylon Elastic Yarn has a moderate thickness and good dyeing properties, which can achieve uniform and durable dyeing effects, making textiles bright and long-lasting in color. A yarn frequently u...

See Details

Polyester blended FDY yarn is a standard 50D yarn made from a blend of polyester and nylon. It combines the characteristics of both fibers and has durability and breathability. It has a wide range of ...

See Details

Low-melt textile FDY yarn can bond with other fibers at a certain temperature to form a strong fabric structure. This property makes it ideal for manufacturing synthetic or reinforced fabrics. This ki...

See Details

High shrinkage blended polyester yarn has a high shrinkage rate and is suitable for textile manufacturing that requires shrinkage treatment, such as making pleated fabrics or textile shaping. Because ...

See Details

Water-repellent blended FDY yarn has good waterproof properties. This characteristic makes Water-repellent blended FDY yarn a greater advantage when making textiles with high waterproof requirements s...

See Details

Stretch durable FDY yarn has good elasticity and can return to its original shape after being stressed, giving the textile a comfortable wearing feel and good ductility. It can fit the contours of the...

See Details

Composite fiber yarn for textile use consists of 48 monofilaments. Relatively thin and composed of multiple filaments, it adds softness and texture to the fabric. This product is suitable for the manu...

See Details

The fibers of 210D water-repellent yarn are relatively thick, making the yarn highly wear-resistant and durable, making it suitable for long-term use. Composite fiber enables yarn to have the advantag...

See DetailsAddress: Duntou industrial park, haian county, nantong city,jiangsu province ,China.

TEL: +86 15850491859

E-mail: sales-betty@hsnylon.com

If You Are Interested In Our Products, Please Consult Us