Product Consultation

Your email address will not be published. Required fields are marked *

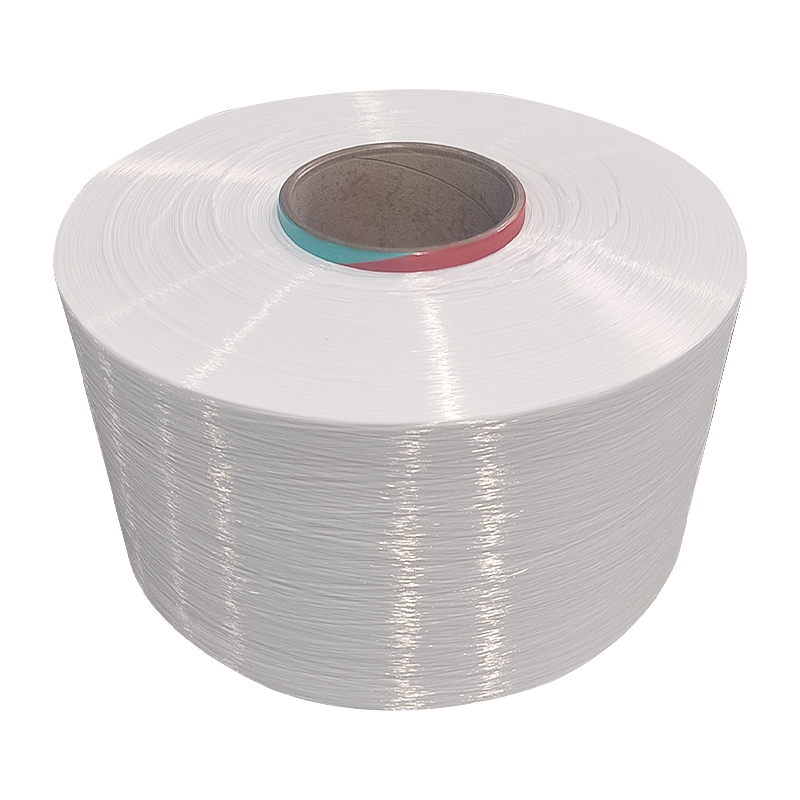

Nylon Elastic Yarn: Why It’s Suddenly a Big Topic in Textile Manufacturing

Jan 15,2026

Are the diameter and surface quality of the nylon monofilament yarn uniform and consistent?

Jan 08,2026

Does nylon multifilament yarn maintain stable performance under high-strength stretching or prolonged use?

Jan 01,2026The quality of nylon elastic yarn is affected by many factors, which run through all aspects of production. From the selection of raw materials to the control of processing technology, to the subsequent storage and use, each link may have an impact on the final performance.

When producing nylon elastic yarn, the purity and quality of the raw materials are crucial. Impurities in the raw materials will affect the uniformity of the fiber, thereby reducing elasticity and strength. During the production process, the control of temperature and humidity is also a key factor. Too high temperature may cause excessive shrinkage of the fiber and affect elasticity, while too low temperature may affect the stability of spinning. Excessive humidity will affect the hygroscopicity of the fiber and make it easy to agglomerate, while too low humidity may cause static electricity problems and affect the molding effect of the fiber.

The control of the spinning process is also an important link in determining the quality of nylon elastic yarn. During the spinning process, the setting of the stretch ratio needs to be precisely adjusted. If the stretch ratio is too large, the fiber is easy to break and the elasticity is reduced; if the stretch ratio is too small, the fiber strength may be insufficient, affecting durability. The control of the cooling and shaping process also directly affects the stability and elastic performance of the fiber. Cooling too fast may cause uneven molecular arrangement and stress inside the fiber, while cooling too slowly may affect the crystallinity of the fiber and reduce its elasticity and resilience.

Dyeing and finishing processes are also important links that affect the quality of nylon stretch yarn. During the dyeing process, the selection and use of dyes will affect the color fastness and feel of the fiber. If the dye molecules are too large, it may affect the permeability and make the fiber color uneven. If the auxiliaries and chemicals used in the dyeing and finishing process are not properly controlled, they may affect the softness and durability of the fiber. The temperature and time control of the finishing process needs to be precise to ensure that the fiber can maintain excellent elasticity without reducing the wear resistance due to excessive treatment.

Storage and transportation conditions also have an important impact on the quality of nylon stretch yarn. If the temperature and humidity in the storage environment fluctuate greatly, the fiber may absorb moisture, expand or shrink, affecting the final use effect. Avoid direct sunlight during storage, otherwise ultraviolet rays may degrade the fiber and affect its service life. Improper packaging during transportation may cause the fiber to be squeezed or rubbed, affecting the appearance and quality.

Will the performance of nylon mother yarn deteriorate due to factors such as ultraviolet rays and oxidation?

2025-02-25

Will the performance of nylon elastic yarn deteriorate during long-term use?

2025-03-11Your email address will not be published. Required fields are marked *

Single Strand Biodegradable Yarn is a single-strand structure, consisting of a single fiber bundle with no multiple strands tangled together. This structure makes the yarn softer, and smoother and exh...

See Details

Colored Nylon Mother Yarn can be processed through spinning, drawing, dyeing and other processes to meet the needs of different textiles. It has good processing adaptability and can be made into vario...

See Details

The diameter of Durable woven nylon mother yarn is 240D, the fiber thickness is medium, and it is suitable for the manufacture of a variety of textiles. This product has good tensile strength and will...

See Details

Nylon stretch sportswear yarn is a yarn used to make sportswear and other clothing that require high breathability. Nylon fiber has good breathability, which helps to wick away perspiration and keep t...

See Details

Double-strand nylon elastic yarn is a composite yarn composed of two strands of yarn. It has high strength, maintains stable performance even in a stretched state, and is not easy to break or deform. ...

See Details

Polyester blended FDY yarn is a standard 50D yarn made from a blend of polyester and nylon. It combines the characteristics of both fibers and has durability and breathability. It has a wide range of ...

See Details

Durable composite nylon yarn has stretch and recovery properties, providing the necessary comfort, fit, and flexibility for clothing and textiles. Made of a blend of nylon fiber and polyester fiber, i...

See Details

Fully stretched polyester blended yarn is made of a blend of polyester and nylon. Polyester itself has good wear resistance. After full stretch processing, the strength and softness of the yarn increa...

See Details

Low-melt textile FDY yarn can bond with other fibers at a certain temperature to form a strong fabric structure. This property makes it ideal for manufacturing synthetic or reinforced fabrics. This ki...

See Details

Cooling brushed durable FDY yarn has high durability and is suitable for manufacturing textiles that require wear resistance and durability. It is not easy to wear out after long-term use. Textiles of...

See Details

Stretch durable FDY yarn has good elasticity and can return to its original shape after being stressed, giving the textile a comfortable wearing feel and good ductility. It can fit the contours of the...

See Details

The fibers of 210D water-repellent yarn are relatively thick, making the yarn highly wear-resistant and durable, making it suitable for long-term use. Composite fiber enables yarn to have the advantag...

See DetailsAddress: Duntou industrial park, haian county, nantong city,jiangsu province ,China.

TEL: +86 15850491859

E-mail: sales-betty@hsnylon.com

If You Are Interested In Our Products, Please Consult Us